Power Semiconductors Weekly Vol. 66

Mitsubishi Electric to Ship Samples of 2.0kV IGBT Module for Industrial Use

Mitsubishi Electric Corporation announced that it will begin shipping samples of its LV100-type T-series 2.0kV insulated-gate bipolar transistor (IGBT) Module for industrial use this May. The new power-semiconductor product is expected to downsize and reduce the power consumption of power-conversion equipment for use with renewable-energy sources. Also, the product will be exhibited at major trade shows, including Power Conversion Intelligent Motion (PCIM) Europe 2022 in Nuremberg, Germany from May 10 to 12.

Power semiconductors for efficiently converting electric power are being increasingly utilized as key devices that can help to lower the carbon footprint of global society. At the same time, efficient power conversion through the deployment of increasingly higher system-operating voltages is being demanded for power grids that use renewable-energy power sources, which has led to the development of power converters rated at DC1500V, the upper limit of the EU’s Low Voltage Directive.

Module samples that Mitsubishi Electric will start shipping soon have a blocking-voltage capability of 2.0kV, which is suitable for DC1500V power conversion equipment used mainly for large-capacity systems of several hundred kW to several MW, including renewable-energy power sources. Adopting 2.0kV withstand voltage semiconductors will enable customers to simplify the design of their DC1500V power-conversion equipment. Also, the latest 7th-generation IGBT and Relaxed Field of Cathode (RFC) diode2 will help to downsize and reduce the power consumption of power-conversion equipment for renewable-energy power supply. In addition, the module’s industrial LV100-type package, which is suitable for large-capacity systems due to its easy-paralleling configuration, will help to simplify large-capacity system designs.

Product Features:

1) IGBT module with 2.0kV withstand voltage will downsize DC1500V power converters

– The new 2.0kV-rated IGBT simplifies the design of DC1500V-rated power converters, including for renewable-energy power sources, which are difficult to design using conventional 1.7kV-rated IGBTs.

2) 7th-generation IGBT and RFC diode reduce power loss in power converters

– Latest (seventh-generation) IGBT with CSTBTTM3 structure and RFC diode optimized for high withstand voltage are suitable for high-voltage, lower-power-loss applications.

3) Industrial LV100-type package will increase capacity of power-conversion systems

– The terminal layout is optimized for easy paralleling and flexible inverter configurations and capacities.

– Three AC main terminals help to spread and equalize current density for increased inverter capacity.

– Integrating the structure’s insulated and copper-base parts and optimizing the internal electrode structure increases thermal cycle life4 and lowers package inductance for enhanced reliability.

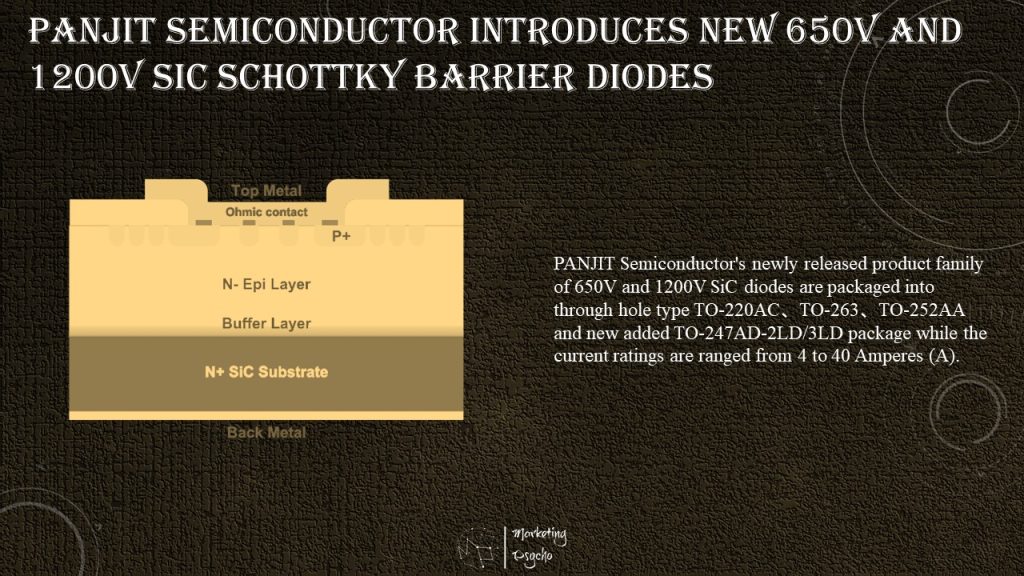

PANJIT Semiconductor Introduces New 650V and 1200V SiC Schottky Barrier Diodes

PANJIT Semiconductor launched its latest family of 650V and 1200V SiC Schottky Barrier Diodes, which provide superior switching performance and higher reliability over silicon-based devices. PANJIT Semiconductor’s newly released product family of 650V and 1200V SiC diodes are packaged into through hole type TO-220AC、TO-263、TO-252AA and new added TO-247AD-2LD/3LD package while the current ratings are ranged from 4 Amperes (A) to 40 Amperes (A).

PANJIT’s SiC Schottky Barrier Diodes provide zero reverse recovery current, low forward voltage drop, temperature independent switching behavior, high surge current capability, and excellent thermal performance. In addition, silicon carbide technology can provide lower conduction losses and deliver stability and high ruggedness throughout -55°C to +175°C operating temperature range.

The new SiC Schottky Barrier Diodes are aimed for engineers designing power conversion circuits for various applications including PV inverters, EV charging pile, industrial motor, telecom and server power supplies, and home appliance where they are facing challenges to deliver smaller footprints at higher system efficiencies. PANJIT Semiconductor offers 650V and 1200V SiC Diode as the ideal solution for next-generation power system designs.

Infineon Introduced New IPM Series CIPOS™ Tiny IM323-L6G

Infineon Technologies AG added a new member to the CIPOS™ Tiny Intelligent Power Module (IPM) family: the CIPOS Tiny IM323-L6G 600 V 15 A. The new IPM is based on TRENCHSTOP™ IGBT RC-D2 switches and state-of-the-art SOI (Silicon on Insulator) gate driver technology to realize maximum efficiency and improved reliability, along with minimized system size and cost. The integration of discrete power semiconductors and drivers in one package allows designers to reduce the time and effort spent on design, significantly shortening the time-to-market. The module is suitable for major home appliances, in particular drives for room air conditioners.

The CIPOS Tiny IM323-L6G is optimized for 3-phase inverters up to 1.2 kW and an operating range of 1 to 20 kHz. The device uses the latest 600 V TRENCHSTOP™ RC-D2 technology with monolithically integrated diode with maximum junction temperature 175 ºC for the switch. Equipped with the rugged new C5SOI gate driver technology for negative voltage spikes at the motor outputs, the IPM ensures a short-circuit capability of at least 3 µs and delivers a high level of protection and fail-safe operation. In case of overcurrent and under voltage, the IPM provides cross-conduction prevention and turn-off of all switches.

The IM323-L6G is molded in a robust and pin-compatible 33 x 19 mm 2 DIP package with built-in NTC which allows high flexibility of the mechanical system design. It thus offers improved package robustness, which results in high reliability. The module also features the latest switching and gate driver technology to achieve the best performance. Furthermore, full in-house production for front-end and back-end provides supply security.

Teledyne LeCroy Develops the Most Accurate Measurement System for GaN and SiC Semiconductor Analysis

Teledyne LeCroy announced the launch of their new DL-ISO High Voltage Optically Isolated 1 GHz Probe and Power-Device test software, which when combined with their High Definition Oscilloscopes (HDO®) offer the most accurate electrical characterization of gallium nitride (GaN) and silicon carbide (SiC) power semiconductor devices.

For more than thirty years, engineers have used silicon (Si) metal-oxide-semiconductor field-effect transistor (MOSFET) and insulated-gate bipolar transistor (IGBT) power semiconductor devices to produce power supplies and power conversion systems. However, consumers are demanding smaller and lighter power supplies and systems, and governments are mandating higher efficiencies. Wide-bandgap (WBG) materials, such as GaN and SiC, switch more than ten times faster than Si in semiconductor devices, and reduce size and weight while increasing efficiency. However, many engineers are implementing WBG semiconductors for the first time, and they need more measurement bandwidth and more accurate and detailed analysis of the semiconductor devices.

The new Teledyne LeCroy DL-ISO High Voltage Optically Isolated Probe provides design engineers with the highest-confidence GaN and SiC power semiconductor device measurements. The new probe has the best signal fidelity, lowest overshoot and best accuracy — 1.5% when combined with Teledyne LeCroy’s industry-leading 12-bit resolution HDOs, nearly twice as good as the only competitor. The 1 GHz bandwidth meets requirements to measure GaN device 1 ns rise times. HDOs also provide up to 20 GS/s sample rate at 12-bit resolution for the most faithful capture and display of high-speed GaN and SiC device signals.

This combination of best signal fidelity, low overshoot, high accuracy, high bandwidth and high sample rate is critically important for successfully implementing GaN and SiC technologies in new designs. Teledyne LeCroy’s new Power-Device software package additionally simplifies the analysis of GaN and SiC devices with automated JEDEC® switching loss and other measurements, and color-coded overlays to highlight the relevant, measured areas.

TankeBlue Semiconductor to Raise Funds through IPO

TankeBlue Semiconductor, a Beijing-based silicon carbide (SiC) substrate supplier, plans to raise funds through an IPO to enhance its working capital for technology R&D and production ramps.

TankeBlue is making progress in its SiC substrate technology R&D and is looking to accelerate production ramps, as the company is gearing up for a boom in demand for 5G, electric vehicle (EV) and solar power applications.

According to qcc.com, a Chinese platform providing information about China-based enterprises, TankeBlue has carried out several rounds of financing since 2009 and has received funding from not only China’s Big Fund but also Hubble Technology Investment, a venture capital arm of Huawei based in Shenzhen.

In 2021, TankeBlue also attracted CNY375 million (NT$58 million) worth of investment from Xinjiang Tianfu Energy – a China-based company primarily engaged in the generation and distribution of heat and electric power, recent updates from qcc.com show.

TankeBlue developed China’s first homegrown 6-inch diameter SiC substrate. Founded in 2006, TankeBlue provides conductive and semi-insulating SiC wafers, as well as other SiC components.

TankeBlue broke ground for a new SiC substrate production base in Beijing in August 2020. Total investment in the new site project, under which 400 sets of single crystal growth furnaces will be established, is estimated at CNY950 million. The project, set for completion this year, will bring in an additional 120,000 pieces of 6-inch SiC substrates annually when the new site comes online.

Navitas Semiconductor at 2022 International Conference on Compound Semiconductor Manufacturing Technology

Navitas Semiconductor, the industry-leader in gallium nitride (GaN) power integrated circuits (ICs), announced that Gene Sheridan, the company’s CEO and co-founder, will be a plenary speaker at this year’s International Conference on Semiconductor Manufacturing Technology (CS MANTECH).

Taking place in Monterey, California from May 9 – 12, the 36th CS MANTECH event brings together around 450 participants from different sectors of the semiconductor supply chain and comprises technical papers, talks, workshops, ‘fireside chats’ and manufacturer exhibits.

Gene Sheridan will deliver his in-person plenary presentation, entitled ‘GaN’s expected Impact on the Power Electronics Industry to Electrify Our World’ at 9.15am PDT on May 10th. The presentation will look at how wide-bandgap (WBG) technologies are set to displace a significant portion of silicon power devices over the next decade and consider the significant market opportunities, challenges, and impacts for GaN to participate in and accelerate the transition from fossil fuels to electrical energy.

“It is a great honor to be invited to deliver a plenary talk at CS MANTECH,” said Gene. “The event is the perfect opportunity to highlight how next-generation WBG power technologies, such as GaN and Silicon Carbide (SiC), will play an essential role across all major segments to significantly improve energy efficiency, reduce global CO2 emissions, and achieve our global environmental sustainability goals to ‘Electrify our World™’”.

Martin Kuball, the 2022 CS MANTECH Technical Program Chairman, adds: “Members of the compound semiconductor manufacturing community are increasingly working with next-generation, wide bandgap materials and are keen to find out more about the role of GaN in the ecosystem. This presentation will give the community insight into the opportunities that lie ahead for widespread GaN adoption.”

Navitas’ GaNFast™ power ICs integrate GaN power and drive plus protection and control to deliver simple, small, fast, and efficient performance. The latest generation of GaNFast ICs with GaNSense™ technology integrates critical, real-time, autonomous sensing and protection circuits which further improves Navitas’ industry-leading reliability and robustness.

Due to advanced-material performance and Navitas’ proprietary AllGaN™ process design kit, GaN power ICs are much smaller than silicon chips, and have 4x-10x lower CO2 footprint to manufacture and ship. Additionally, due to their superior level of performance, higher system efficiencies can be achieved to significantly reduce wasted electrical energy and CO2 emissions. In datacenters, GaN has the potential to save over 10 million tons of CO2/year through increased efficiency. For electric vehicles (EV), it is estimated that an upgrade from silicon to GaN in on-board chargers (OBCs), DC-DC converters and traction drive inverters, could accelerate the worldwide transition from internal combustion engines to EVs by 3 years, and reduce total road-sector emissions by 20% per year.

With over 40 million devices shipped and no GaN-related field failures, Navitas GaN is proven in the high-end fast charger market. This technology is now available with a 20-year warranty – a critical accelerator for GaN’s adoption in data center, industrial automation, solar and EV markets.

To register for CS MANTECH 2022 click here.

Wolfspeed Webinar: Speed Up Silicon Carbide Adoption with Useful Power Module Reference Designs

Led by applications such as EV and traction drives, energy storage systems, and DC fast chargers, modern designs have demanding power needs. With these strict performance requirements, Silicon Carbide has quickly become a semiconductor of choice. For engineers looking to implement Silicon Carbide in their high-performance designs, Wolfspeed provides reference designs to serve as the building blocks to accelerate the design pipeline.

Key Take-Aways:

- Wolfspeed’s Silicon Carbide power module offerings and accompanying reference designs and evaluation tools

- How to Accelerate the design process by utilizing Wolfspeed’s reference designs in a variety of applications

- Practical design considerations, with system-level and application-specific requirements to prioritize performance metrics

- Date: May 19, 2022

- Time: 5 PM CEST

Subscribe to Power Semiconductors Weekly and watch it on YouTube every Tuesday.

If you prefer a monthly update about the world of power semiconductors delivered to your e-mail address, please, subscribe to Marketing Psycho Power Semiconductors newsletter.