Power Semiconductors Weekly Vol. 65

Infineon Extends CoolSiC™ M1H Technology Portfolio with 1200 V SiC MOSFETs

Infineon Technologies AG introduced a new CoolSiC™ technology: the CoolSiC™ MOSFET 1200 V M1H. The advanced silicon carbide (SiC) chip will be implemented in a widely extended portfolio using the popular Easy module family, along with discrete packages using .XT interconnect technology. The M1H chip offers high flexibility and is suitable for solar energy systems, such as inverters, that have to meet peak demand. The chip is also ideal for applications such as fast EV charging, energy storage systems and other industrial applications.

The latest advancements of the CoolSiC base technology enable a significantly larger gate operation window that improves the on-resistance for a given die size. Simultaneously, the larger gate operation window provides a high robustness against driver- and layout-related voltage peaks at the gate, without any restrictions even at higher switching frequencies. Along with the M1H chip technology also the related housings have been adopted in technology and package variants to enable higher power densities and more options for design engineers to improve on application performance.

The M1H will be integrated into the popular Easy family to further improve the Easy 1B and 2B modules. In addition, a new product which enhances the Easy 3B module with the new 1200 V CoolSiC MOSFET, will also be launched. The roll-out of new chip sizes maximizes flexibility and ensures the broadest industrial portfolio. With the M1H chip, the on-resistance of the modules can be significantly improved, making the devices more reliable and efficient.

Furthermore, with a maximum temporary junction temperature of 175°C, overload capability increases, enabling higher power density and coverage of failure events. Compared to its predecessor, the M1, the M1H has implemented a small adoption of the internal R G, enabling the switching behavior to be easily optimized. The dynamic behavior is maintained with the M1H chip.

In addition to the Easy module family, the CoolSiC MOSFET 1200 V M1H portfolio includes new ultra-low on-resistances 7 mΩ, 14 mΩ and 20 mΩ in the TO247-3 and TO247-4 discrete packages. The new devices are easy to design-in, especially due to the gate voltage overshoots and undershoots with the new maximum gate-source voltage down to -10 V, and come with avalanche and short-circuit capability specifications.

Infineon’s. XT interconnection technology, previously introduced in the D 2PAK-7L package, is now also implemented in a TO-footprint. The thermal dissipation capabilities are enhanced by more than 30 percent compared to a standard interconnection. As a result, such thermal benefit can be used to increase the output power of up to 15 percent. Alternatively, it can be used to increase the switching frequency to further reduce the passive components in e.g. Electric vehicle (EV) charging, energy storage or photovoltaic systems for enhanced power density and reduced system cost. Without changing the system operating conditions, the .XT technology will lower the SiC MOSFET junction temperature, therefore significantly increasing the system lifetime and power cycling capabilities. This is a key requirement in applications like e.g., servo drives.

The new 1200 V CoolSiC MOSFET M1H additions further enhance the optimization potential for SiC-based applications, with fast implementation of clean energy and energy efficiency in a global world.

Leapers Semiconductor to Introduce HPD Series SiC MOSFET Power Modules for Automotive Application

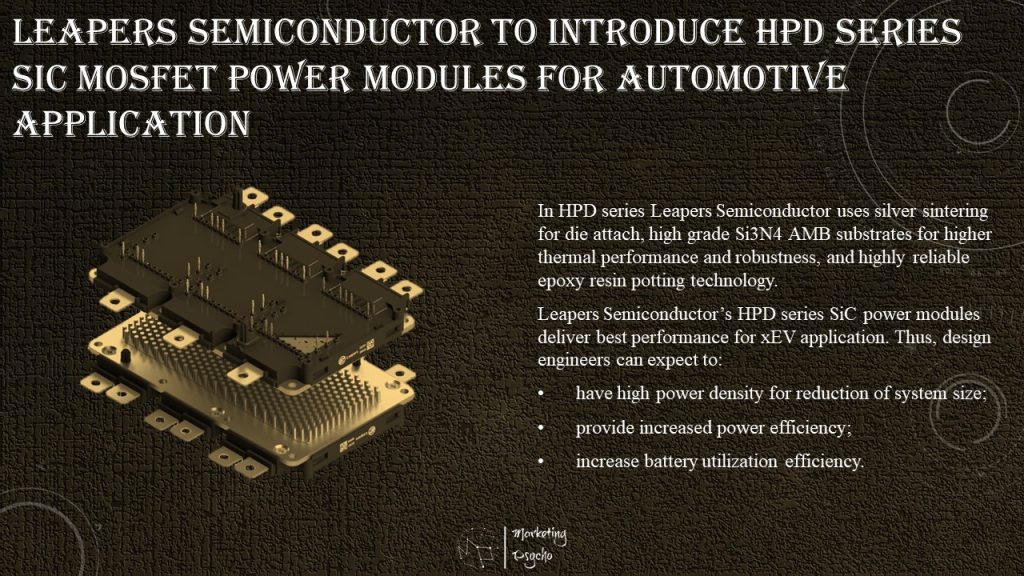

As an innovative developer and manufacturer of SiC power modules, Leapers Semiconductor Co., Ltd. (Leapers Semiconductor) introduced its HPD series SiC power modules designed specifically for the electrical vehicles.

HPD series are 1200 V three-phase water-cooled SiC MOSFET power modules in industry recognized automotive footprint, which are optimized for traction inverters and motor drives. HPD series provide high power density and efficiency for inverters designed for longer driving range and lower battery cost.

To deliver best in class automotive grade HPD SiC power modules Leapers Semiconductor use its patented Arcbonding™ technology.

Unlike traditional Al wire bonding technology used by many manufacturers of automotive grade power semiconductors, Arcbonding™ patented chip surface connecting technology ensures the reliability of SIC modules reach automotive application requirements, while significantly reducing parasitic resistance and parasitic inductance. Besides, Arcbonding™ proved to significantly reduce static losses, improve power cycling, and the ability of short time impulse current. And even if 6-10 SiC dies are connected in parallel, HPD series power modules still work consistently.

In HPD series Leapers Semiconductor uses silver sintering for die attach, high grade Si3N4 AMB substrates for higher thermal performance and robustness, and highly reliable epoxy resin potting technology.

Leapers Semiconductor’s HPD series SiC power modules deliver best performance for xEV application. Thus, design engineers can expect to:

- have high power density for reduction of system size;

- provide increased power efficiency;

- increase battery utilization efficiency.

Leapers Semiconductor will present HPD series SiC MOSFET power modules during the PCIM Europe trade show which will be held in Nuremberg, Germany, May 10-12, 2022. All visitors and participants can meet Leapers Semiconductor’s team at the Booth 520 in Hall 7.

SanRex Launches Discrete 1200V Voltage SiC MOSFETs

SanRex launched SiC MOSFETs with a current capacity of 50A, using a TO-247 package with a 4-pin structure that achieves fast switching and low loss.

In addition to the existing module products (150A and 100A), SanRex added a 50A discrete product to meet a wide range of customer requirements.

Power devices are used in a variety of applications in the automotive and industrial fields. SiC (silicon carbide) power devices are expected to be key devices for energy conservation in high-current and high-voltage applications because of their low loss and high-speed operation that exceeds that of conventional Si (silicon). This product reduces unnecessary inductance by incorporating a SiC MOSFET chip with a built-in reflux diode function, and achieves high-speed switching and low loss by adopting a 4-pin structure that brings out the performance of SiC MOSFETs.

Product features:

- Proprietary low-loss internal wiring that maximizes the performance of SiC MOSFETs and a dedicated package with high heat dissipation and high insulation

- The 4-pin structure reduces the effect of inductance on the source pins, resulting in faster switching and reduced energy loss

- SiC MOSFET chip with built-in reflux diode function that can reduce unwanted inductance for ideal switching

- Industry’s top class short-circuit withstand capacity to realize safe design of equipment against short circuit breakdown, which is said to be a weak point of SiC MOSFETs

- Chip that achieves high efficiency in actual use has an on-resistance characteristic that remains unchanged even at high temperatures (150°C)

- High threshold gate characteristics that are resistant to malfunction against noise at high frequency drive (threshold voltage 4.0V (Typ.))

Main applications:

- Industrial Inverter

- Uninterruptible power system (UPS)

- EV Battery Charger

- Various Switching Mode Power Supplies

This product complies with the RoHS directive (2011/65/EU and (EU)2015/863).

By expanding the lineup of SiC MOSFET-based products, SanRex will contribute to higher reliability and efficiency as well as smaller size and lower cost of power supplies.

BorgWarner Receives U.S. Department of Energy Award for DC Fast Charger

BorgWarner, a global product leader in delivering innovative and sustainable mobility solutions for the vehicle market, has received a $4.09 million U.S. Department of Energy (DOE) Award to design and develop a cost-effective, advanced direct current fast charger (DCFC). BorgWarner received one of 25 research, development and demonstration projects which aim to advance electrification, reduce vehicle emissions and improve EV charging infrastructure.

BorgWarner will lead the 36-month DCFC project in coordination with US-based suppliers and research partners, including Michigan State University, eTransEnergy, Cityfi, the State of Michigan, and Barton Marlow, in addition to component supplier support from Wolfspeed, Inc. Kickoff of the project is slated for Q1 of 2022.

“As a leader in the electrification field, we are proud to receive this funding to take our current state-of-the-art technology to the next level in order to fit the industry’s needs and create a cleaner and more energy-efficient world,” said Davide Girelli, President and General Manager, BorgWarner Morse Systems. “We are excited to once again partner with the DOE and collaborate with our project partners to develop the next generation of DCFC technology.”

The project’s purpose is to develop the next generation DCFC system at a 20-30% cost reduction with increased power density, reduced energy losses, decreased package size and improved reliability. Ultimately, the new technology will enable widespread adoption of similar chargers. BorgWarner and its project partners will be working toward delivering a charger with 10 charge points collectively capable of a total of 350kW. With the flexibility and adaptability of BorgWarner’s single stage power conversion and power module architecture, the charger will be able to deliver power to up to five vehicles at a time (with five others plugged in and ready to be charged). Based on project design, the charger will demonstrate product scalability from 150kW to 350kW or greater and will produce output power from single 25kW power modules.

DCFCs allow for charging at a much faster rate than conventional Level 2 alternating current (AC) chargers with the same ease of accessibility. The DC power can be supplied directly to the vehicle’s battery, resulting in higher efficiency. Additionally, because DCFCs allow for higher power levels, charging stations can deploy numerous charge points so that multiple vehicles can be charged simultaneously. The unit will be designed to support current EVs, with the flexibility to easily be upgraded to support potential future battery electric vehicles that operate at higher voltages.

“Paired with our longstanding reputation of delivering excellence, BorgWarner has a seasoned team that is ready to tackle the target areas of innovation to make our DCFC goals come to fruition,” continued Girelli. “Our single conversion architecture, power module design and packaging, power electronic capabilities and module building block approach will be the factors that ensure a successful project launch for the EV market.”

Infineon to Expand Existing Backend Operations in Indonesia

Infineon Technologies AG expands its existing backend operations in Indonesia: PT Infineon Technologies Batam to purchase real estate from PT Unisem, a member of Unisem Group. The premises close to Infineon’s existing backend manufacturing site include manufacturing buildings that will double Infineon’s production area in Batam when fully operational. In the course of this expansion, Infineon’s Batam site will increase its focus on the assembly and test of automotive products.

“Infineon is making another step in strengthening its global operations network. We are committed to investing into continued structural growth and to strengthen the resilience of our supply chain,” said Alexander Gorski, Executive Vice President and responsible for Infineon’s global Backend Operations. Dr. Thomas Kaufmann, Executive Vice President and COO of Infineon’s Automotive Division, said: “In view of increasing demand for automotive semiconductors and to the benefit of our customers, this purchase is allowing us to add backend capacities faster than with the greenfield construction of a new site”.

Production is expected to start in 2024. The expansion in Batam is part of Infineon’s long-term investment strategy, which foresees investments of approximately €2.4 billion for the 2022 fiscal year. PT Infineon Technologies Batam is a backend manufacturing site and employs over 2,000 employees. It is located within the Batamindo Industrial Park and part of the Indonesia-Singapore-Malaysia growth triangle.

SEMICON Southeast Asia 2022 to Focus on Semiconductor Supply Chain Sustainability and Resilience

Semiconductor supply chain sustainability and resilience will come into sharp focus as SEMICON Southeast Asia, the region’s premier gathering of the semiconductor and microelectronics industry, returns to the Setia SPICE Convention Centre & Arena in Penang, Malaysia following a two-year hiatus due to the pandemic.

To be held from 21-23 June 2022, SEMICON Southeast Asia 2022 will commemorate Malaysia’s 50th Year of Manufacturing Excellence and celebrate Penang’s reputation as the Silicon Valley of the East, built on decades of manufacturing excellence and industrial experience.

“The rise of the cloud, 5G deployment, connected vehicles, and digitization have created unprecedented demand for high-performance computing,” said Linda Tan, president of SEMI Southeast Asia. “As the backbone of the connected world, the semiconductor industry must maintain a sustainable balance of demand and supply to ensure the resiliency and flexibility of its supply chain. Insights into integrated supply chain networks are critical in enabling the industry to identify and manage any disruptions. SEMICON Southeast Asia 2022 will delve into this and much more as we continue our work to support industry players in Malaysia and around the region.”

Themed Forward as One–Building A Resilient and Sustainable Electronics Supply Chain in Southeast Asia, SEMICON Southeast Asia 2022 will gather industry experts for the latest developments, innovations and trends across the semiconductor supply chain. Semiconductor manufacturing equipment companies, private-and-public partners and industry players will connect to explore new collaboration and growth opportunities.

“The electrical and electronics (E&E) industry is the cornerstone and strength of Malaysia’s manufacturing sub-sector, and the sector has grown tremendously, accelerated by the demands for semiconductors and chips during the pandemic,” said Datuk Arham Abdul Rahman, Chief Executive Officer of the Malaysian Investment Development Authority (MIDA). “MIDA is honored to have worked with SEMI for the past eight years to promote and update our industry stakeholders on the technological advancements. We continue to value this partnership since the exposure to emerging trends and industry networking opportunities offered and gained at previous SEMICONs have been important to our prominent E&E industry players.”

“MIDA is committed to expanding our manufacturing ecosystem by encouraging and pursuing high-quality, high-technology investments driven by global digitization in this industry in order to strengthen Malaysia’s supply chain, product innovation and talent development capabilities,” Rahman said. “SEMI Southeast Asia 2022 is perfectly aligned with our aspirations of encouraging the development of the industry through proactive and guided measures while allowing potential investors to explore Malaysia’s competitive advantages as an ideal investment destination.”

As part of Malaysia’s jubilee celebration, attendees at SEMICON Southeast Asia 2022 will feature a robust lineup of experts and thought leaders from semiconductor organizations around the world.

SEMICON Southeast Asia 2022 Highlights

- Smart Manufacturing Pavilion will focus on technologies that can increase manufacturing efficiency as well as sustainable practices to minimize impact on the environment

- Smart Mobility Pavilion will showcase technologies and innovations that are driving urban mobility

- IoT Pavilion will highlight existing and emerging technologies and applications enabled by semiconductor innovation

- Technical Forums will offer insights on industry trends whilst providing networking and other information-sharing opportunities

- CxO Summit sessions will feature industry opinion leaders

- Business Matching Programs will connect industry players to explore business and technology partnerships and opportunities

- Workforce Development Pavilion will feature a career fair and talks by industry experts to help the industry build its talent pipeline

- Career Fair and SEMICON University Program will support workforce development in Malaysia

To register for SEMICON Southeast Asia 2022 or for more information, visit the conference website.

Subscribe to Power Semiconductors Weekly and watch it on YouTube every Tuesday.

If you prefer a monthly update about the world of power semiconductors delivered to your e-mail address, please, subscribe to Marketing Psycho Power Semiconductors newsletter.