Power Semiconductors Weekly Vol. 120

Vitesco Technologies and ROHM Have Signed a Long-Term SiC Supply Partnership

Vitesco Technologies, a leading international manufacturer of modern drive technologies and electrification solutions, has secured strategically important capacities in energy-efficient silicon carbide power semiconductors through a long-term supply partnership with ROHM – worth over one billion US dollars until 2030. The development partnership with the manufacturer ROHM, which began in 2020, created the basis for the supply partnership now signed in Regensburg. Vitesco Technologies’ advanced inverters with integrated ROHM SiC chips will be adopted by two customers, to be applied inside electric vehicle powertrains. Vitesco Technologies will start supplying a first series project as early as 2024. The company is thus even ahead of the originally targeted timeline.

SiC devices enable the design of particularly efficient power electronics, such as those needed for electric car inverters. SiC chips are a key technology, particularly for high voltages and for vehicles with demanding range targets and optimum overall efficiency. During the existing development partnership with ROHM the relevant SiC chips were further optimized for use in automotive inverters starting in 2024.

Silicon carbide belongs to the so-called wide bandgap semiconductors, whose wide bandgap (simplified: the energy gap between the non-conductive state and the conductive state of the electrons in the material) enables lower electrical resistance, fast and low loss switching chips for power electronics. At the same time, SiC chips are more thermally resistant, so that the power density of electronics can be increased.

Thanks to these features, SiC electronics have reduced conversion losses compared to conventional silicon (Si). Especially at high voltage levels such as 800 V, SiC inverters are more efficient than Si models. Since 800 V is the prerequisite for fast and thus convenient high-voltage charging, SiC devices are at the beginning of a worldwide boom. Reduced conversion losses in the inverter are also significant for the overall efficiency of electric driving and thus for range. Competition for sufficient capacities in components made of this high-tech material is correspondingly fierce.

Toyoda Gosei Develops Horizontal GaN Power Device of World-Class High-Voltage, High-Speed Operation

Toyoda Gosei Co., Ltd. and Powdec K.K. have jointly developed a high-performance horizontal GaN power device that will lead to improved performance in the power converters used in solar power generation and other equipment.

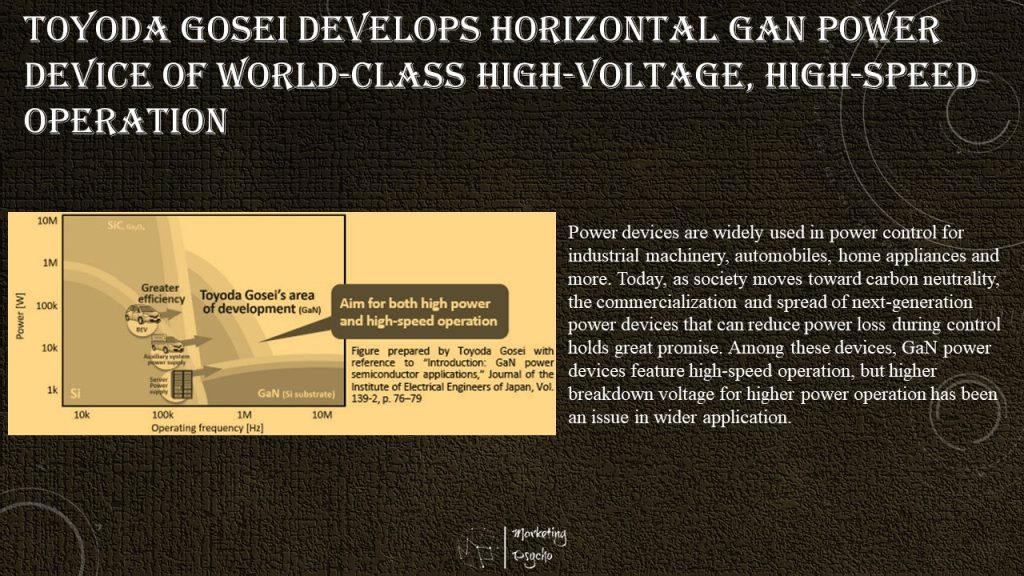

Power devices are widely used in power control for industrial machinery, automobiles, home appliances and more. Today, as society moves toward carbon neutrality, the commercialization and spread of next-generation power devices that can reduce power loss during control holds great promise. Among these devices, GaN power devices feature high-speed operation, but higher breakdown voltage for higher power operation has been an issue in wider application.

World-class power of 800V and On/Off operation of one millionth of a second was confirmed using a module equipped with an originally designed GaN power device under development by Toyoda Gosei and Powdec. This demonstration of a power device that offers both high-voltage and high-speed operation is promising for reduced power loss in solar power generation and other benefits. The companies are aiming to assure stable continuous operation and durable quality for early commercialization.

Airbus and STMicroelectronics Collaborate on Power Electronics for Aircraft Electrification

Airbus, a global pioneer in the aerospace industry, and STMicroelectronics, have signed an agreement to cooperate on power electronics Research & Development to support more efficient and lighter power electronics, essential for future hybrid-powered aircraft and full-electric urban air vehicles.

The collaboration builds on evaluations already conducted by both companies to explore the benefits of wide bandgap semiconductor materials for aircraft electrification. Wide bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) have superior electrical properties compared with traditional semiconductors like silicon. They enable the development of smaller, lighter and more efficient high-performance electronic devices and systems, particularly in applications requiring high power, high frequency, or high-temperature operations.

The co-operation will focus on developing SiC and GaN devices, packages, and modules adapted for Airbus’ aerospace applications. The companies will assess these components by conducting advanced research and tests on demonstrators, such as e-motor control units, high and low voltage power converters, and wireless power transfer systems.

Toshiba Launches 600V Super Junction N-channel Power MOSFET Series with Ultra-Low RDS(on)

Toshiba Electronics Europe GmbH has introduced a new series of N-channel power MOSFETs. The first product in the 600V DTMOSVI series is the TK055U60Z1, which is based on Toshiba’s latest-generation process with a super junction structure.

The new MOSFET features an RDS(on) of only 55mΩ – a 13% improvement over similar devices in the company’s established DTMOSIV-H series. In addition, the RDS(on) x Qgd, which is the figure of merit for MOSFET performance, is improved by approximately 52%. Target applications include high-efficiency switching power supplies in data centers, power conditioners for photovoltaic generators, and uninterruptible power systems.

The new product employs the popular TOLL package, which features a Kelvin connection for the signal source terminal. As a result, the source wire’s inductance has less impact, reducing switching oscillation, which enhances switching performance when the MOSFET operates at high gating speeds. The applied pin shaping ensures proper solder connections, increases mounting reliability and makes visual inspection easier.

The maximum channel temperature (Tch) of the new product is 150°C. The typical RDS(on) of 47mΩ is specified at a gate-source voltage of 10V.

Typical total gate charge (Qg), gate-drain charge (Qgd) and input capacitance (Ciss) are 65nC, 15nC and 3680pF, respectively. These factors will allow the new device to switch at the fastest possible speeds.

Toshiba will continue expanding its 600V DTMOSVI series lineup, and the already released 650V DTMOSVI series products, to support energy conservation by reducing power loss in switching power supplies.

Chinese SiC Power Device Provider AscenPower Mass Produces SiC Chips for Vehicle and Industrial Control

AscenPower, a Chinese SiC power device supplier, has begun mass-producing a series of vehicle and industrial control SiC chips. The products include 1200V, 16 milliohms/35 milliohms, and other specifications.

Guangzhou-based AscenPower is currently the largest SiC chip manufacturing project in China that focuses on vehicle chips, with the ability to support large-scale industrial clusters and the entire industry chain. It has signed contracts with more than 10 COT clients. It plans to complete the construction of production capacity of 10,000 6-inch SiC chips per month by the end of this year, the company’s chairman Xiao Guowei said on June 17.

AscenPower was founded in 2021 with RMB7.5 billion ($1.05 billion) investment to construct production lines for 240,000 6-inch and 240,000 8-inch SiC chips annually.

Its products are mainly power devices including SiC SBD/JBS, MOSFET, and IGBT, which are used in new energy vehicles, industrial power supplies, smart grids, and photovoltaic power.

Alpha and Omega Semiconductor Announces Logo Redesign that Reflects its Commitment to Developing Cutting-Edge Power Management Solutions

Alpha and Omega Semiconductor Limited (AOS) announced it has redesigned its corporate logo to better reflect the company’s position as a cutting-edge technology provider and its ongoing commitment to innovations.

The updated logo has a fresh, contemporary look but keeps some original elements that reinforce AOS’ history of success and industry stability. The logo redesign was part of the complete upgrade of the AOS website that launched in January 2023.

“We are excited to reveal the new AOS logo to our customers. It showcases how the company has evolved and grown into the global power management solutions leader it is today, said Stephen Chang, CEO of AOS. “I believe the logo also captures our innovative spirit while representing AOS’ solid industry reputation in delivering design and manufacturing excellence and outstanding customer support.”

Subscribe to Power Semiconductors Weekly and watch it on YouTube every Tuesday.

If you prefer a monthly update about the world of power semiconductors delivered to your e-mail address, please, subscribe to Marketing Psycho Power Semiconductors newsletter