On Time Delivery (abbreviated as OTD) is a performance indicator that measures the proportion of orders completed on time and in full over a certain period of time and is one of the elements of supply chain management. There are various methods for calculating this indicator, each company chooses the right one for itself.

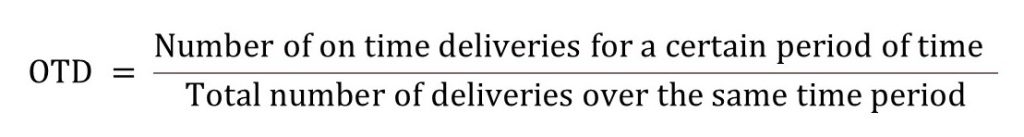

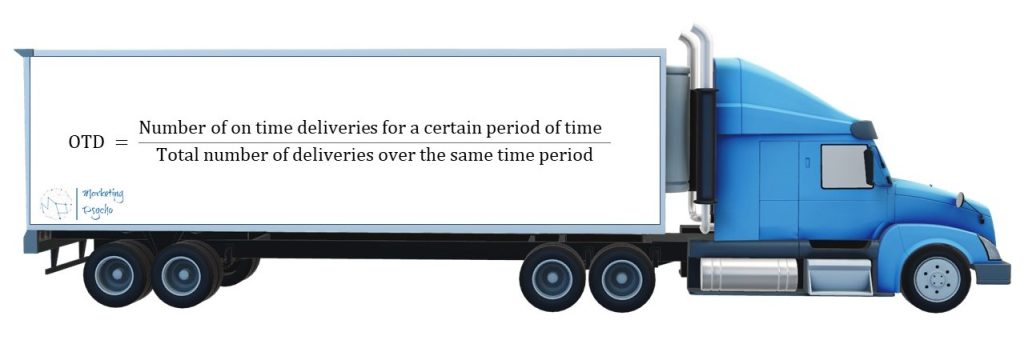

The most general formula is as follows:

The results are recorded as a percentage.

Usually, formulas that help calculate OTD are built into your company’s ERP system. Three main dates are usually important for OTD tracking:

- Request Date is the date when the client asked to deliver, the wish delivery date for the client.

- Promise Date is the date when you promised the customer to deliver.

- Delivery Date is the date when the delivery actually took place.

If you have these three data, then you can evaluate the following indicators for OTD:

- Proportion of orders delivered on time, relative to the requested date

- Proportion of orders delivered on time, relative to the promised date

There are different On Time Delivery target values for different business lines. As a rule, it should not be less than 95%, but other options are possible. If the percentage is below the benchmark, it should be a signal to you that there are problems at some stage of the order execution. You need to analyze the situation and identify the root cause. To do this, you can use the 5 Whys method. After identifying the main problem, develop a plan to eliminate it and monitor the progress of its implementation.

For more correct tracking of the OTD indicator, companies rarely choose a specific date, often they specify a period or window during which delivery can occur. A typical On Time Delivery window can be expressed as -5+0, that is, it is 5 days earlier than the fixed date, 0 days later than this date. For example, if you have determined the delivery date on July 21, then the delivery will be considered completed on time in the period from July 17 to July 21, the delivery of the goods after July 21 will be considered a violation of the delivery time. You can also set other time windows for your company. Many organizations use the ABC approach for this.

Products are divided into categories depending on the criteria you choose, and the cost of the product is often used. The most expensive products are category A, the next ones are B and C. Class A orders will have the narrowest window. Each letter down will have a slightly larger window size.

To correctly track the On Time Delivery indicator, you must make sure that your ERP system meets your expectations, since some software is not agile or reliable enough to include too many different priorities for product classification. You should also define the measurement criteria precisely. Often, the supplier and the customer have discrepancies in OTD indicators, this is due to different approaches in tracking some data.

For example, the supplier counts only the working days of the delivery when the customer includes calendar days in the calculation, or the supplier closes the indicator when the goods are shipped from the warehouse, that is, it takes into account the date of shipment, at the time when the customer uses the date of delivery of the goods to their warehouse. These possible discrepancies in calculations should be kept in mind when analyzing work with a specific customer.

Timely delivery improves cooperation with your customers, ensures reliable delivery, and, most importantly, customer loyalty. It is important to set the right expectations with your customers and meet them. Customer satisfaction, including meeting order deadlines, should be an important priority for your business. On Time Delivery indicator will help you reach your goals.

You can find more related information in Marketing Strategy section of Marketing Psycho blog.