Power Semiconductors Weekly Vol. 5

GaN Systems Ships 20,000,000 GaN Transistors

GaN Systems, the global leader in GaN (gallium nitride) power transistors, announced the shipment of its 20 Millionth GaN transistor and that its factory partners are on schedule to complete a 40X capacity expansion in 2021.

Its comprehensive, best-in-class line of 100V and 650V products with proven reliability and demonstrated benefits such as higher efficiency and power density while reducing size, weight, and costs are all contributing factors to GaN’s growing market acceptance versus legacy Silicon and new SiC transistors.

Additionally, GaN is significantly cheaper than SiC, which requires a more expensive and complex manufacturing process. Costs required to increase capacity for SiC are 10X higher than for GaN. For GaN, low CAPEX for capacity combined with very low substrate cost results in GaN transistors being lower cost than SiC. And GaN is half the price it was just a few years ago, making system costs similar or lower than power systems built with legacy Silicon transistors.

CEO Interview: The Next Generation of GaN Power ICs

Alex Lidow, CEO of Efficient Power Conversion (EPC) talks about the potential for gallium nitride GaN devices as discrete power devices and with integration.

Then there’s traction drives that current use silicon IGBTs and increasingly SiC. “The answer is I don’t know. IGBT is the best choice below 650V. SiC is the best at 900V and above. Then there’s the 650 to 900V and that’s where traction drives are either IGBT, SiC or GaN. GaN will take over that if integration becomes a key element. SiC if they can get the cost down. IGBT will take over if the other two don’t do those things.”

Alex says that “The thing that limits GaN today is material quality, trapping electrons limits the size of the device and the size of the electric field so the devices are bigger than they need to be because of that limit. There is about 64x improvement in material quality with the electric field limitation. Not just the crystal growth but the design of the layers. We use the silicon underneath for the integration of the active devices.”

The next step is the integrated devices combining the silicon logic and GaN power.

ROHM SiC MOSFETs Solve Design Challenges for Leading Solar Energy Company Midnite Solar

ROHM Semiconductor recently announced that Midnite Solar, the leading producer of a wide range of alternative energy products based in Arlington, WA, utilizes ROHM’s silicon carbide MOSFETs to drive efficiency and reduce system cost.

Four products new to the US market – the Hawkes’s Bay 600VDC to 48VDC 6000W MPPT solar charge controller, powerful Barcelona dual MPPT charge controller, MNB17 advanced battery-based charger/inverter, and 120/240V Rosie inverter/charger – all benefit from the high performance and proven reliability of ROHM’s SiC technology.

“Silicon carbide solves a key challenge,” explains Robin Gudgel, Midnite Solar’s principal owner and engineering manager. “Regular silicon MOSFETs have a very slow body diode,” he details. “Therefore, trying to make an inverter work as a charger where it must run bidirectionally is very difficult. We were looking at an IGBT pair in combination with another diode, but silicon carbide is such a good solution, and ROHM’s devices did not require any significant design changes, so it was an obvious choice.”

Richardson Electronics, Ltd. Continues Expansion of Power Management Capabilities with SemiQ Third Generation SiC Diode Modules

Richardson Electronics, Ltd. announced the availability of the new SemiQ third generation SiC diode modules. All four modules have been qualified via the JEDEC standard reliability test and come in a SOT-227 package. Samples provided globally upon request.

With over 20M hours of testing, GEN3 is designed and built for reliability and ruggedness with high breakdown voltage and high surge current rating. SemiQ’s third-generation SiC modules are available in 650V/1200V, 50A/100A configurations and suite the applications including but not limited to:

- Renewable energy

- Electric Vehicle Charging Stations

- UPS

- Solar Power

- Fuel Cell Power Systems

Infineon Bets on Strong EV Growth

Infineon Technologies AG expects continuing strong momentum in chips for electric vehicles, a market that is growing rapidly in Europe and China as compared to the U.S.

The German-based chipmaker estimated 40% growth in sales of its products used in EVs for fiscal year 2020, compared to 2019. In calendar 2020, the overall EV market grew by 36% versus the prior year and that growth is expected to double into 2021, coming strongly from hybrids but also battery EVs.

CEO Reinhard Ploss also said the company will move up its starting date of its new 300 mm power semiconductor plant in Villach by a quarter to fourth fiscal quarter, which starts in July.

US Chip Industry Calls on Biden Administration to Fund Factories

A group of US chip companies on Thursday sent a letter to President Joe Biden urging him to provide “substantial funding for incentives for semiconductor manufacturing” as part of his economic recovery and infrastructure plans.

The chief executives of major US firms such as Intel, Qualcomm, Micron and Advanced Micro Devices signed onto the letter.

It comes as a global chip shortage has idled factory lines at Ford and General Motors, with executives at the automakers predicting billions in lost profit.

The missing chips are mostly manufactured in countries such as Taiwan and Korea, which dominate the industry.

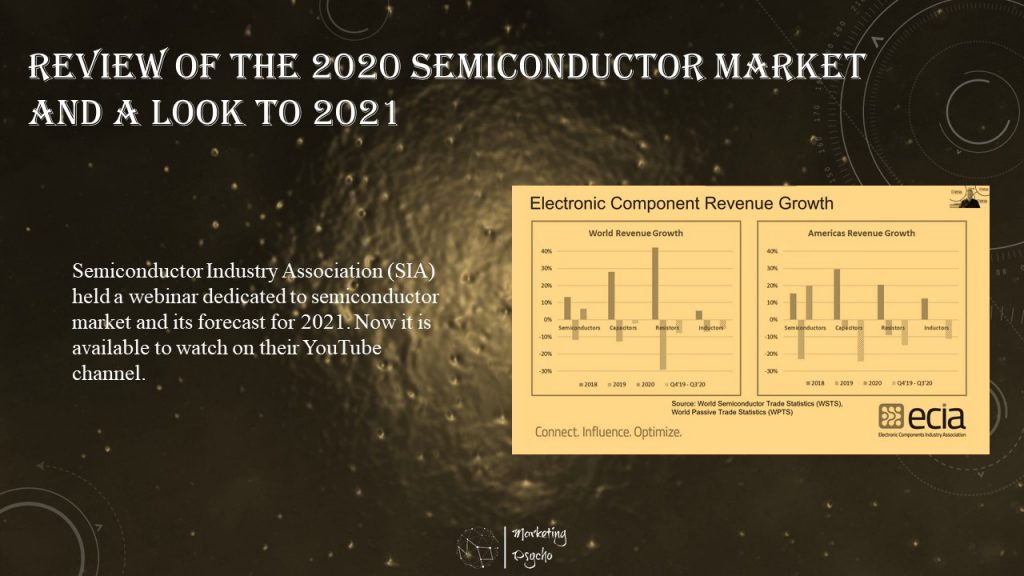

Review of the 2020 Semiconductor Market and a Look to 2021

Semiconductor Industry Association (SIA) held a webinar dedicated to semiconductor market and its forecast for 2021. Now it is available to watch on their YouTube channel.

2020 proved to be one of the more unique years in recent times in terms of semiconductor market performance. Pre-2020 market forecasts were quickly and fundamentally rethought at the start of the year, as the COVID-19 pandemic upended the world. Significant uncertainly on how semiconductor sales would react to the pandemic existed for much of the year, especially during the first half.

As monthly World Semiconductor Trade Statistics sales figures rolled in through the latter half of 2020, it became clear 2020 sales would end up better than most had initially feared.

SemiSel 5: Simplify Power Semiconductor Selection

Power electronics engineers understand the complexity of power module selection for their specific applications. With SemiSel 5, Semikron offers a new simulation tool to ease this burden.

Starting with a blank sheet of paper, Semikron team created SemiSel 5 around the needs of power electronics developers. With its brand new user interface, power module selection is even easier through only five simple steps.

In the first section of this webinar, Martin Röblitz will guide you through the new features of SemiSel 5. He will also show which additional features are available especially for registered users and how they make SemiSel even better.

In the second section, he will run a complete simulation. In only five steps, he will get from the selection of the topology to the detailed analysis of the simulation results.

With this knowledge, you will have the ability to select the power modules you need faster and with more confidence.

Find more information about power semiconductors in Marketing in Power Electronics section of the website.